Safe, Healthy, and Sustainable

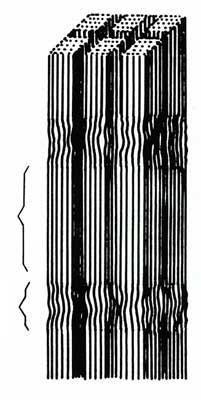

Cellulose Microfibrils

Crystalline Region

Paracrystalline Region

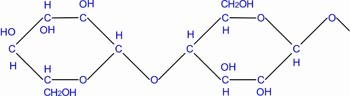

Most of fiber-rich plants contains hemicellulose, lignin, glucose, and cellulose. By going through hydrolysis process, cellulose is collected to be further processed.

The insoluble crystalline fraction in each microfibril of cellulose is than extracted to make Microcrystalline Cellulose.

Finally, MCC is co-polymerized with other hydrocolloids to create a stabilizer with a unique characteristics, commonly called Colloidal Grade MCC

The insoluble crystalline fraction in each microfibril of cellulose is than extracted to make Microcrystalline Cellulose.

Finally, MCC is co-polymerized with other hydrocolloids to create a stabilizer with a unique characteristics, commonly called Colloidal Grade MCC

FibroTec MCC is produced from selected wood-pulp from forests worldwide with reliable sustainability program to fulfill our responsibility toward social and ecological balance. Our unique MCC has gone through a systematic controlled hydrolysis and co-polymerization process in a HACCP, FSSC-22000, Halal, and Kosher conforming facility.

FibroTec in Your Products

Adding FibroTec in your product has many benefits. It optimizes the functionality of other ingredients to give you the best performance in you products. FibroTec gives you these benefits by creating a three-dimensional matrix with water or other liquid media. This network suspends and traps particles to prevent any ingredient separation, color separation and moisture migration.

To take full advantage of the functionality of FibroTec, it is essential to first let FibroTec to develop its weak gel network with the liquid media by mixing it well with the main ingredient of the product. In liquid products, it is necessary to disperse FibroTec in a high-speed mixer. Furthermore, using a homogenizer for product dispersion will help FibroTec to function at its best.

In a semi-solid products, it is also best to disperse FibroTec in liquid before adding other ingredients. When adding FibroTec in your product, it is advised to add salt, acid and calcium at the end of the process.

To take full advantage of the functionality of FibroTec, it is essential to first let FibroTec to develop its weak gel network with the liquid media by mixing it well with the main ingredient of the product. In liquid products, it is necessary to disperse FibroTec in a high-speed mixer. Furthermore, using a homogenizer for product dispersion will help FibroTec to function at its best.

In a semi-solid products, it is also best to disperse FibroTec in liquid before adding other ingredients. When adding FibroTec in your product, it is advised to add salt, acid and calcium at the end of the process.

Microcrystalline Cellulose

Microcrystalline Cellulose (MCC) is derived from plant fibers that are widely available in trees, grass, cotton, and other fiber-rich plants. It is a naturally non-caloric indigestible dietary fiber that is widely used as binders and anticaking agent in food and pharmaceutical industries.