Dairy Products

Applying FibroTec in Dairy Beverages

There is no single stabilizer can be applied in dairy as a stand-alone stabilizer. Finding the correct blending of FibroTec MCC and other stabilizers and emulsifier is very important.

When applying FibroTec based stabilizing system, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C.

Homogenization is necessary for final step before sterilization. Different characteristics of products require different pressure setting.

Lastly, it is recommended to add calcium, vitamins, acid and salt at the end after all other ingredients are added.

When applying FibroTec based stabilizing system, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C.

Homogenization is necessary for final step before sterilization. Different characteristics of products require different pressure setting.

Lastly, it is recommended to add calcium, vitamins, acid and salt at the end after all other ingredients are added.

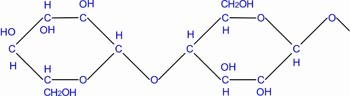

Microcrystalline Cellulose

The presence of milk fat, lactose, calcium, vitamins, mineral and salts, protein and enzyme in milk creates a very complex structure in dairy products. The additional of other ingredients in many different dairy products sometimes resulting in instable product. Such complicated system requires accurate processing and stabilizing system.

Microcrystalline Cellulose (MCC) is a key stabilizer for dairy. Not only MCC suspends solids and eliminates separation and sedimentations, it adds mouth-feel and creaminess in dairy.

Microcrystalline Cellulose (MCC) is a key stabilizer for dairy. Not only MCC suspends solids and eliminates separation and sedimentations, it adds mouth-feel and creaminess in dairy.